NaB Seal

Outline

The NaB Seal is a flexible, eco-friendly waterproof material that is produced by combining asphalt, SBS Rubber, and Butyl Rubber, which does not cause waterproof layer lift and maintains gel condition semi-permanently without using dilution materials such as heating or solvents.

Use

Application to areas, etc. requiring waterproofing of buildings and civil structures;

1. Underground building rooftop, installation tunnel, subway

2. Underground roads, various underground structures in the communal district

3. Exterior walls of wastewater treatment plants, sewage treatment plants, and waste disposal plants

4. Cracks and joint filling parts, leak parts of construction and civil engineering structures

Characteristics

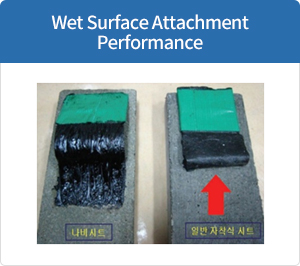

1. Excellent adhesion under wet conditions

-

Increased wet surface adhesion

-

Decreased wet surface adhesion

-

2. It can be constructed regardless of the moisture contained in concrete.

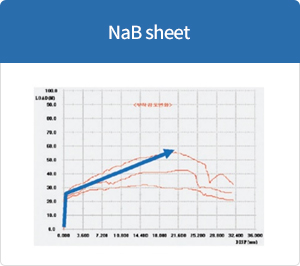

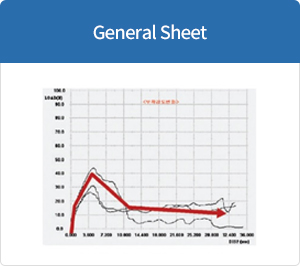

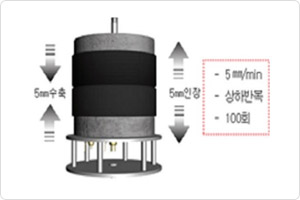

3. Excellent response performance to the behavior and vibration of structures

-

Structure Behavior Responsiveness

-

All clear

4. The maintenance cost is low because it is easy to re-repair even if a leak occurs due to a defect generated during construction.

5. Excellent adhesion performance with heterogeneous materials (concrete, steel, plastic, etc.)

-

No leakage of coating and joints

-

No leakage of heterogeneous sheets

and joints

Key Characteristics of NaB Seal Overcoming the Limitations of Existing Waterproof Technology

-

Limitations of existing waterproof technology (cause of water leakage).

- Lack of adhesion performance under

wet conditions- Lack of responsiveness to structure

behavior and vibration- Lack of adhesion with heterogeneous materials (concrete, steel, plastic, etc.)

-

Properties of NaB Seal

- Excellent adhesion performance

under wet conditions- Excellent response performance to

the behavior and vibration of

structures- Excellent adhesion performance with heterogeneous materials (concrete,

steel, plastic, etc.)

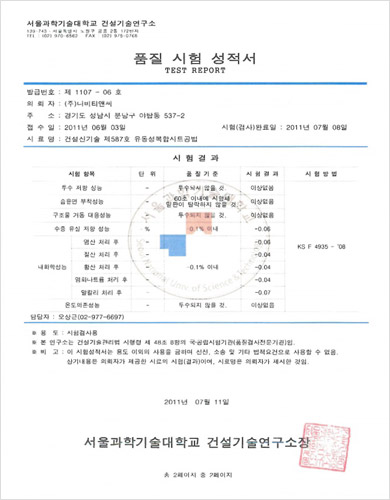

Test Report

| Item | Criteria | Standard | |

|---|---|---|---|

| Water pressure resistance | Not to fail | KS F 4935 | |

| Wet Surface Attachment Performance | The test specimen base shall not fail within 60 seconds |

||

| Structure Behavior Response Performance | Not to fail | ||

| Underwater Loss Resistance Performance | Mass rate of change within -0.1% |

||

| Chemical resistance performance | Hydrochloric acid | Mass rate of change within -0.1% |

|

| nitric acid | |||

| sulfuric acid | |||

| Sodium Chloride | |||

| Alkali | |||