NaB Seal Story

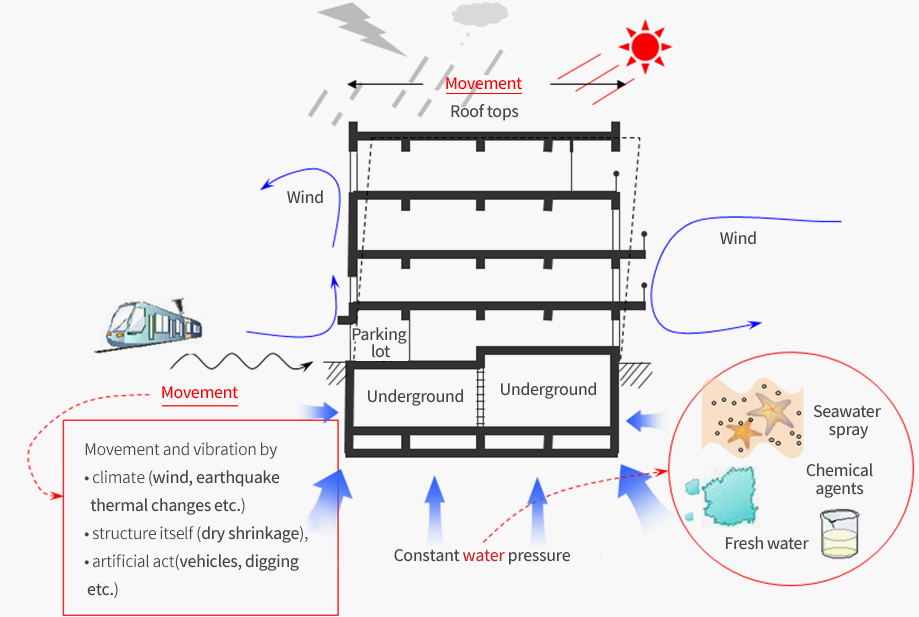

Our main living spaces, such as rooftops, outer walls, underground spaces, and civil structures

(subways, tunnels, bridges, trough structures, etc.), are constantly exposed to various deteriorating conditions

(wind, water pressure, typhoon, vibration, chemical water, salinity, pollution, etc.).

Development conditions for optimal waterproof technology

-

Vibration, Behavior,

Wind Pressure

Responsiveness -

Workability for wet

surfaces, low temperature

surfaces, contaminated

surfaces, etc.

-

Self-healing

performance,

temperature

stability -

Chemical resistance (salt, acid, alkali, ozone resistance)

-

Performance required

by the environment

of use (insulation, fire

resistance, seismic performance) -

Eco-friendly

(dance agents,

carbon reduction, recycling)

We need to develop eco-friendly waterproof materials that can sufficiently respond to building environmental factors such as temperature/water quality effects, physical factors such as uneven subsidence, vehicle operation, and groundwater pressure.

Key Characteristics of NaB Seal Overcoming the Limitations of Existing Waterproof Technology

-

Limitations of existing waterproof technology (cause of water leakage).

- Lack of adhesion performance under

wet conditions- Lack of responsiveness to structure behavior and vibration

- Lack of adhesion with heterogeneous materials (concrete, steel, plastic, etc.)

-

Properties of NaB Seal

- Excellent adhesion performance under

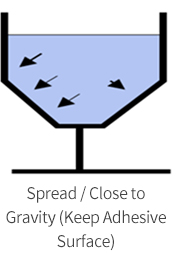

wet conditions- Excellent response performance to the behavior and vibration of structures

- Excellent adhesion performance with heterogeneous materials (concrete, steel, plastic, etc.)

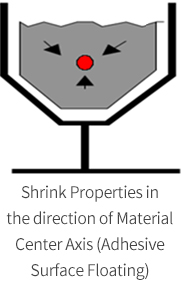

A NaB seal is a substance that contrasts with a solid material that secures the internal center axis of intermolecular binding and maintains its form in a formal manner, and is a malformed substance that is maintained by intermolecular.

Unlike the physical properties of a solid that causes damage and lift by acting on the inner center axis contrary to the direction of the surface when external forces such as vibration and movement occur on the background, NaB Seal always has a relatively weak internal binding force.

The biggest reason for frequent waterproof defects and re-leakage of conventional general waterproofing methods is that the inherent characteristics of the hardened material as it contracts in the direction of the center axis of the material cause the attachment surface with the waterproof material to rise.

NaB seal have the property of not permanently hardening and moving in the direction of gravity due to wet attachment, spreading and adhering to the waterproof surface. As a result, the adhesive surface can be maintained even if the structure is moved or broken, and it has key characteristics that prevent leakage. This is the source technology that makes NaB seal the most different from general waterproof materials.

Liquidity gel characteristics and application effects

Components: Rubber asphalt + viscous polymeric materials + water stabilizers + other additives

| Division | Characteristic | Effect |

|---|---|---|

| Viscosity | Wet, pollutant adhesive, easy to repair (continuity in foreign materials, new and old materials) |

Ensure constructability and quality |

| Expandability | Self-healing of damaged areas | Ease of maintenance, long-term durability |

| Flexibility | Shock, vibration safety, long-term fatigue resistance | Ensure crack responsiveness |

| One liquid type | Easy handling, storage, ease of construction, shortening construction period (no curing period required) |

Easy to quality control |

| Eco-friendly | No Solvent, Industrial Waste Free | Eco Friendly |

| Economic feasibility | Shortening construction period, facilitating maintenance, and increasing durability |

Reduce maintenance costs |

NaB seal is a key waterproof material of NaB T&C with adhesive, expandability, flexibility, and eco-friendly by combining rubber asphalt, viscous polymer materials, underwater stabilizers, and other additives.

Hazardous substances not used = Eco friendly, work safety, fire safety

Characteristics of Enamel Shinna, a representative diluent in waterproof construction

It's very volatile.

It exists in the form of harmful gases in the air and is absorbed by the human body through breathing.

It is highly addictive, which harms the brain and nerves, causing anesthesia and headaches.

It smells bad and is toxic.

There is always exposure to fire risk.

It is a representative environmental pollutant such as destruction of ozone layer.

In the case of general waterproofing method, diluents such as toluene, xylene, etc., which are organic solvents, are mixed to improve workability,

so they are exposed to the risk of fire as well as the stability of the constructor. However, NaB seals are eco-friendly materials that do not use these

organic solvents. (Environmental Signing Certification Products)

A NaB seal that moves like a skin.

NaB seal is an excellent waterproof material developed to overcome the technical limitations

of existing general waterproof materials, and is the crystal of key technology for realizing the water-free

space (Water Zero Zone) pursued by NaB T&C.